Quality

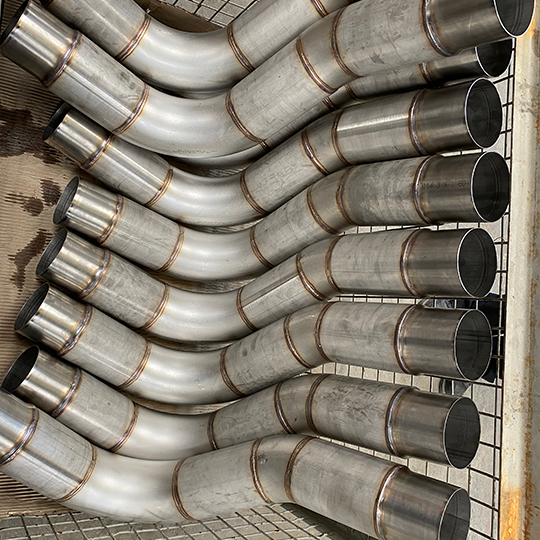

All tubular assemblies are measured and verified to customer specifications using co ordinate measuring machines with full inspection data available upon customer request.

We are fully conversant with ISAR, PPAP and PSW procedures. We utilise a full shop floor data capture system which feeds straight into our production control software. This enables all live works orders to be progressed in real time on the shop floor. All finished parts are given a unique batch number and bar code enabling full part and process traceability.

We will design and build any assembly fixture required to maintain the customers specified tolerances. Along with this we also offer Brazing and Silver Soldering. Our welders are experienced in fabricating a wide range of materials including mild steel, stainless steel, aluminium and other special alloys.

Finishing

On site powder coating and degreasing facility.

We also supply parts electro plated, polished and other surface finishes as required.

Other In House Facilities

- CNC saws up to 250mm diameter

- CNC Milling

- CNC Drilling

- Turning

- Guillotine (2m x 4mm)

- Press Brake (30 tonne)

- Power Press (30 tonne)